Technology in Harmony: Direct Lithium Extraction using a true Simulating Moving Bed with our ION-IX multiport valves.

Puritech DLE multiport valve technology

Puritech provides this technology by using our CCIX multiport rotary valves, a true Simulating Moving Bed (SMB). With currently 11 active projects worldwide, of which a few commercial, covering both geothermal brine and salt lake brine, Puritech is proving its expertise in DLE. Our multiport valve technology has flow rate capacities from a few liters per hour up to more than 400 m³/h within one single installation. This with temperatures varying from ambient up to 75°C. Each multiport valve is tailor made to meet the clients needs. This allows process flexibility, choice of sorbent/resin and plant layout.

Advanced DLE technology

With currently 11 running projects within the DLE market, a wide range of flow rates for DLE processing have been executed.

Pilot trails with Puritech equipment:

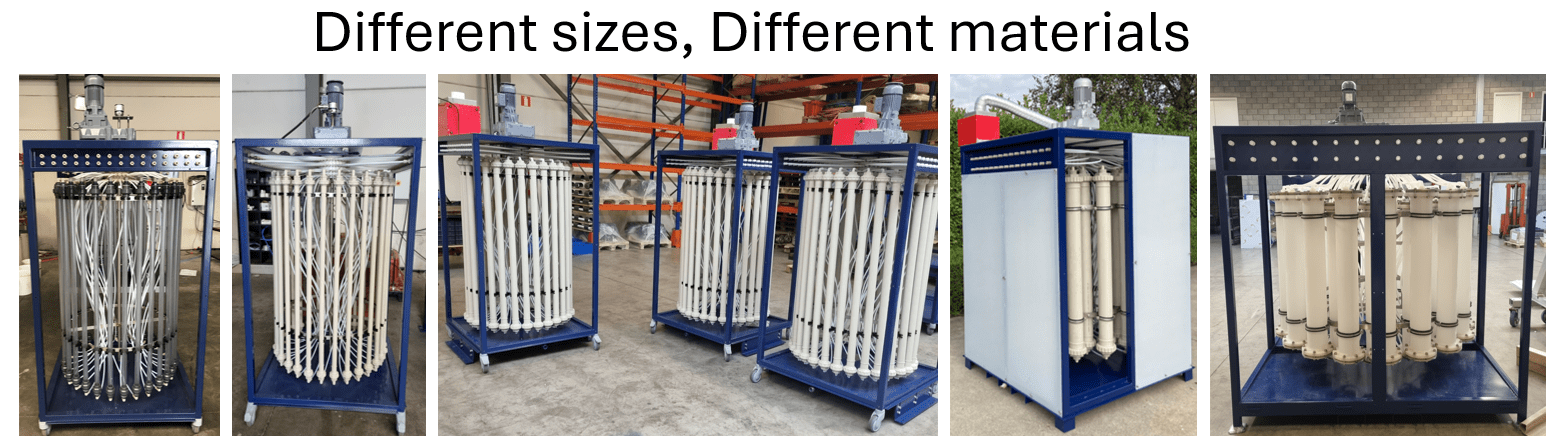

In order to define the correct CCIX process parameters within DLE, pilot trials can be recommended. Our Puritech piloting equipment allows maximum process flexibility on different levels:

- Process configuration changes are easily done.

- A wide range of flow rates can be tested.

- Different temperatures from ambient up to 90°C.

- A compact layout which allows minimal space taken.

Our pilot units can be custom made following the clients needs.

More information can be found on our page.

Demo plants for small scale commercial units

Once the major process parameters are defined, a small scale demo plant can be installed. This represents a commercial scale installation with the possibility to change flow rates, temperatures and concentrations, resulting in the most efficient DLE processing. Our ION-IX multiport rotary valve is used in this setup, proving its innovative design and exceptional efficiency.

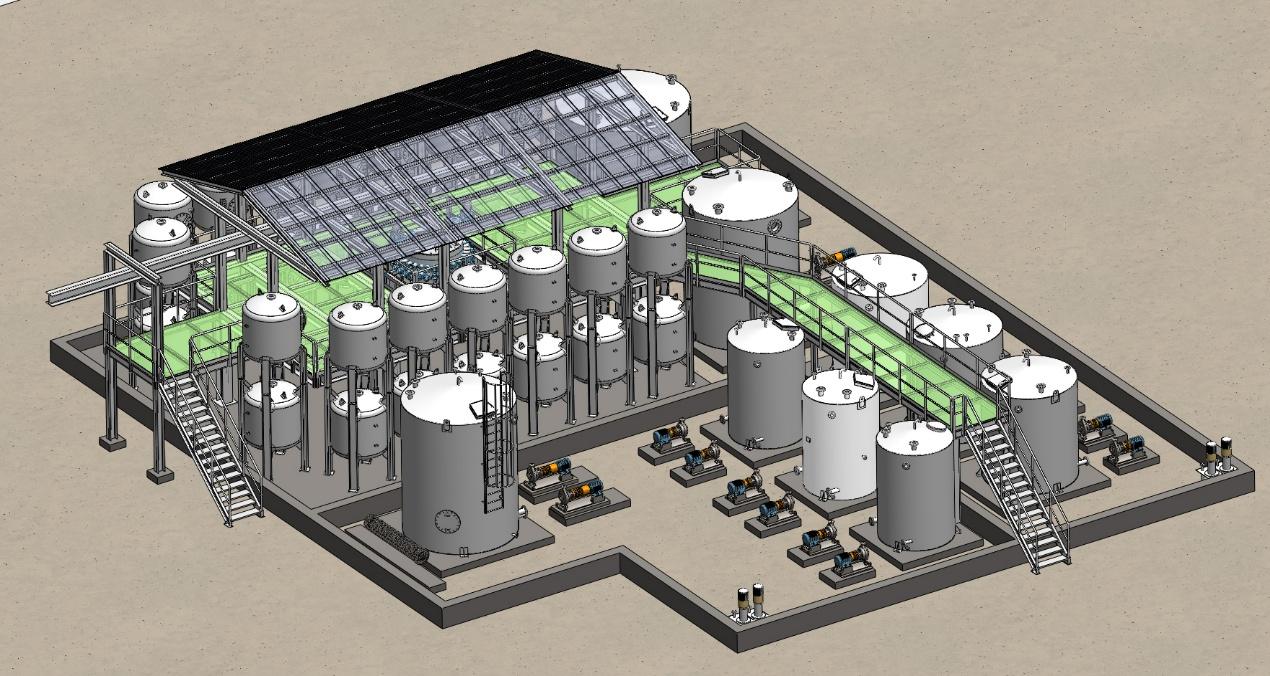

Commercial DLE plants

With just one single commercial scale multiport valve setup, flow rates up to more than 400 m³/h can be handled. Custom made installations ensure maximum efficiency for each demand.

The importance of sorbents/resins

Our equipment falls within CCIX technology so therefore the use of correct sorbents and resins if of high importance to allow maximum efficiency and yield. Puritech's technology is highly flexible in the use of sorbents/resins.

The most important sorbent/resin parameters are the follwing:

- Loading capacity.

- Kinetic performance.

- Mechanical strength.

- Complete lithium /impurities separation.