Elegant solution

Realising the growing market potential of ion exchange, PuriTech has taken CCIX system

design to a new level. It sought solutions to problems that have restricted the development

and broader use of current systems.

Our company has efficiently reversed a tried and tested approach to distributing fluids to ion exchange cells, or chambers, used by companies, to create a cleverly conceived system. This elegant solution not only improves liquid-resin contact efficiency, but also reduces plant operation costs and requires a smaller investment in capital equipment.

Our company has efficiently reversed a tried and tested approach to distributing fluids to ion exchange cells, or chambers, used by companies, to create a cleverly conceived system. This elegant solution not only improves liquid-resin contact efficiency, but also reduces plant operation costs and requires a smaller investment in capital equipment.

Advantages

ION-IX Multiport distribution valve

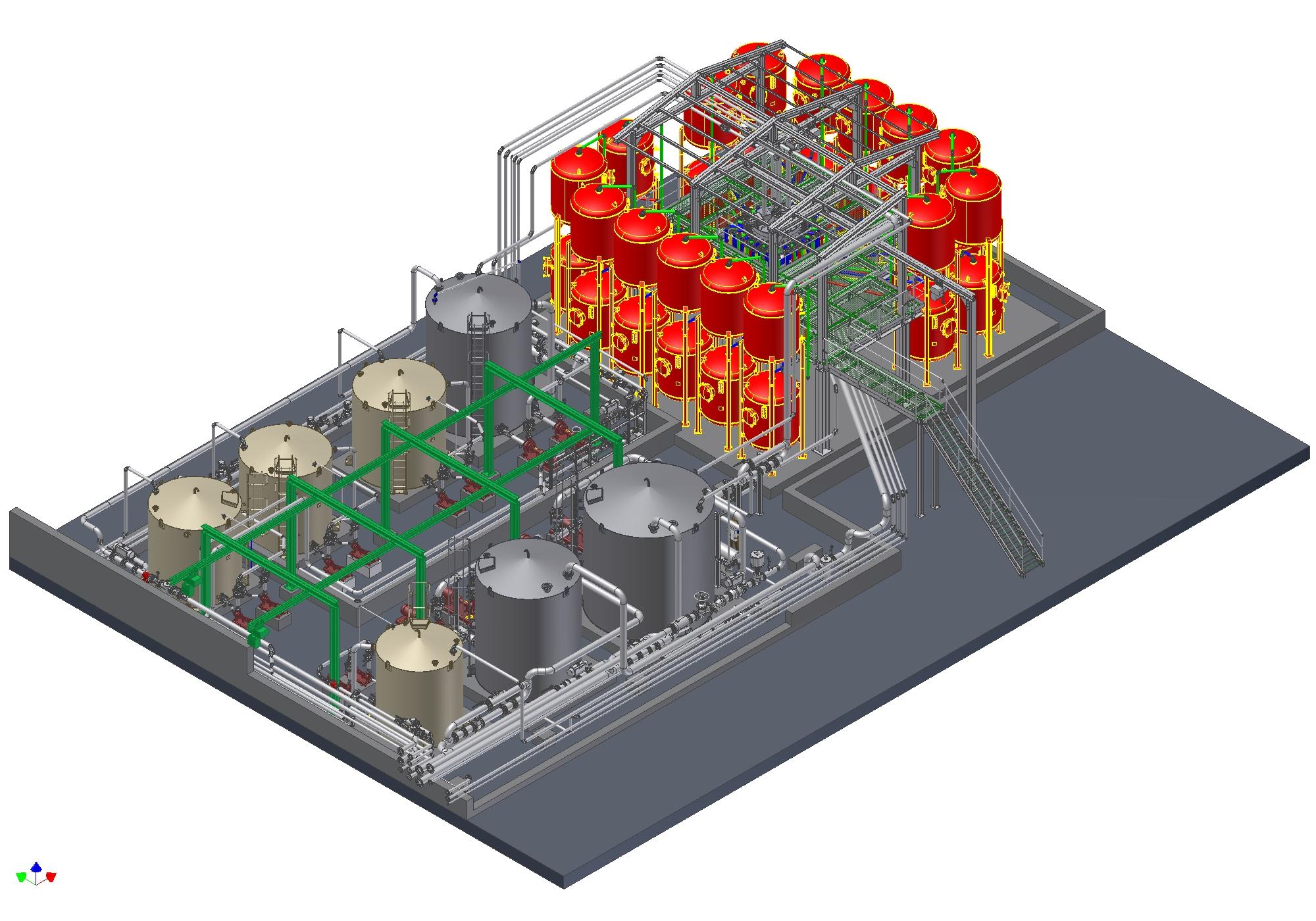

PuriTech uses an ION-IX multiport valve, creating a process system for CCIX. The patented multiport valve distributes different flow streams to several resin cells in a continuous way and determines whether the resin is in an adsorption, a regeneration or a rinsing cycle.

This technology is markedly different from other CCIX systems that are available in the market place. Instead of using a carousel to move the cells around the valve, the process disc within the ION-IX multiport valve rotates around and distributes the different streams to the cells containing ion exchange resin or other adsorption materials.

During a full rotation of the inner process disc, each resin cell is subjected to an entire sorption cycle.

Adaptive and versatile

Because the system's only moving part sits internally of the ION-IX valve body, the valve and

ion exchange vessels can be easily accessed and therefore simplifies maintenance

procedures. This also provides the possibility to use rigid pipes between the valve and the ion

exchange vessels, instead of flexible hoses.

The ion exchange vessels can be positioned in any desired pattern, providing maximum installation flexibility and making it possible to build compact systems.

The ion exchange vessels can be positioned in any desired pattern, providing maximum installation flexibility and making it possible to build compact systems.

Higher efficiency

The use of smaller and shorter resin beds allow maximum resin usage.

The mass-transfer zone in a standard ion exchange plant is typically a small section of the

actual operating bed length. This small production section, where mass transfer takes place,

passes as a transfer zone through the bed. Using conventional methods this results in a large

amount of saturated non-active resin while adsorption still takes place.

Counter-current contacting on a continuous basis does not suffer these limitations as the

mass transfer zone is maximized over several ion exchange vessels at the same time and

saturated resin is continuously replaced by fresh, active resin.

This efficiency results in an economical advantage reducing the resin inventory and together with high levels of fluid-recovery, reduces the chemical/water usage drastically.

This efficiency results in an economical advantage reducing the resin inventory and together with high levels of fluid-recovery, reduces the chemical/water usage drastically.

Lower capital investment

In some applications the capital investment on specific projects can be reduced by 20–40%.

For example, a like-for-like comparison of an ION-IX unit and a typical carousel system — both rated at 40 m3/h — reveals that by using PuriTech's ION-IX technology, the investment cost can be reduced by about 35%.

ION-IX is targeted at a wide range of industries, and plants based on the technology are set to displace some fixed-bed units.

Even existing countercurrent systems have been switched over to the ION-IX technology due to being more cost-effective and requiring a smaller investment.

For example, a like-for-like comparison of an ION-IX unit and a typical carousel system — both rated at 40 m3/h — reveals that by using PuriTech's ION-IX technology, the investment cost can be reduced by about 35%.

ION-IX is targeted at a wide range of industries, and plants based on the technology are set to displace some fixed-bed units.

Even existing countercurrent systems have been switched over to the ION-IX technology due to being more cost-effective and requiring a smaller investment.