Nickel Laterite

Lateritic nickel ore deposits are surficial, weathered rinds formed on ultramafic rocks. Nickel laterites

are a very important type of nickel ore deposit, they comprise 73% of the continental world nickel

resources. They are growing to become the most important source of nickel metal for world demand.

Nickel is a hard, silver white metal that has industrial applications related to its strength, corrosion resistance, high ductility, good thermal and electrical conductivity and catalytic properties. Its primary use is in manufacture of stainless steel, steel alloys and superalloys.

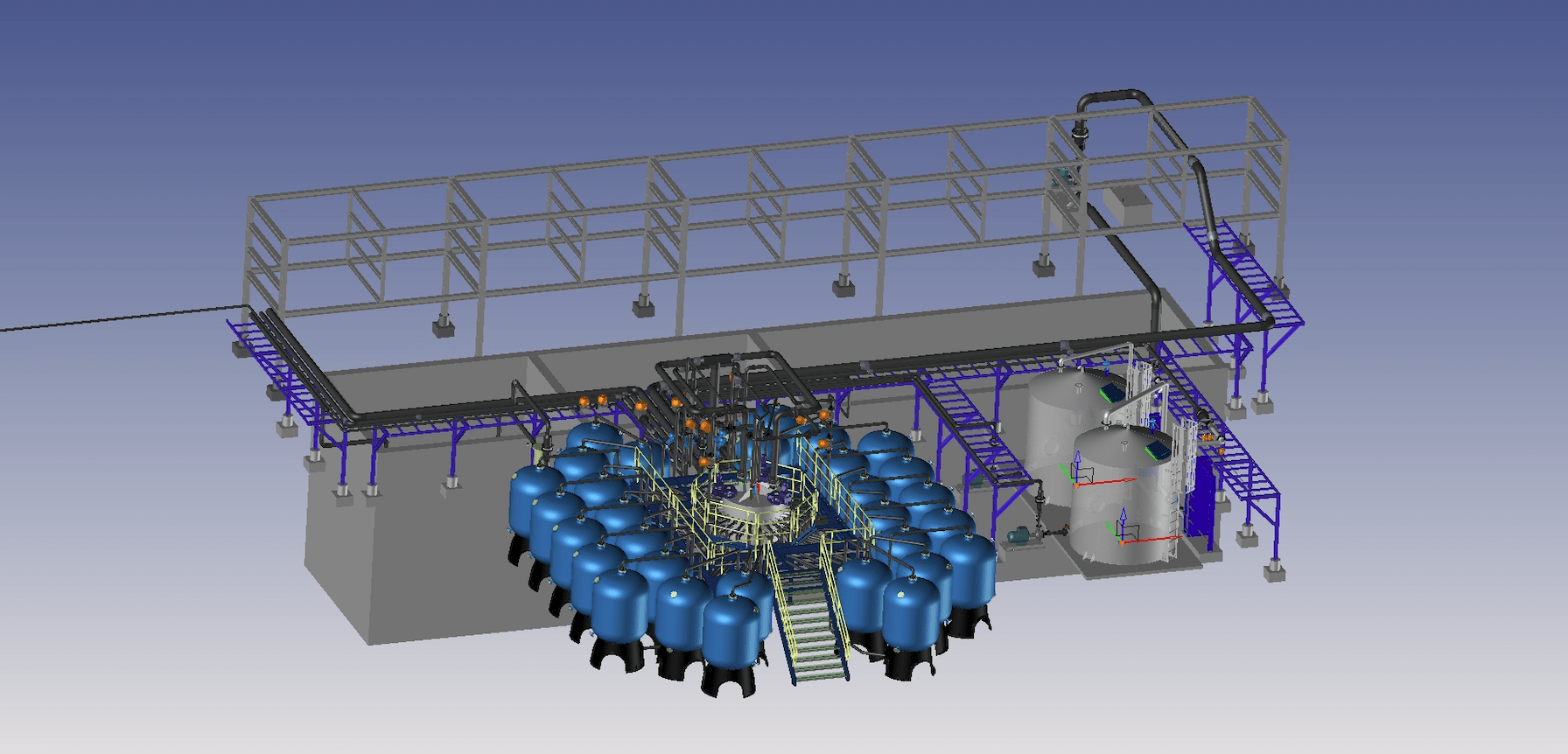

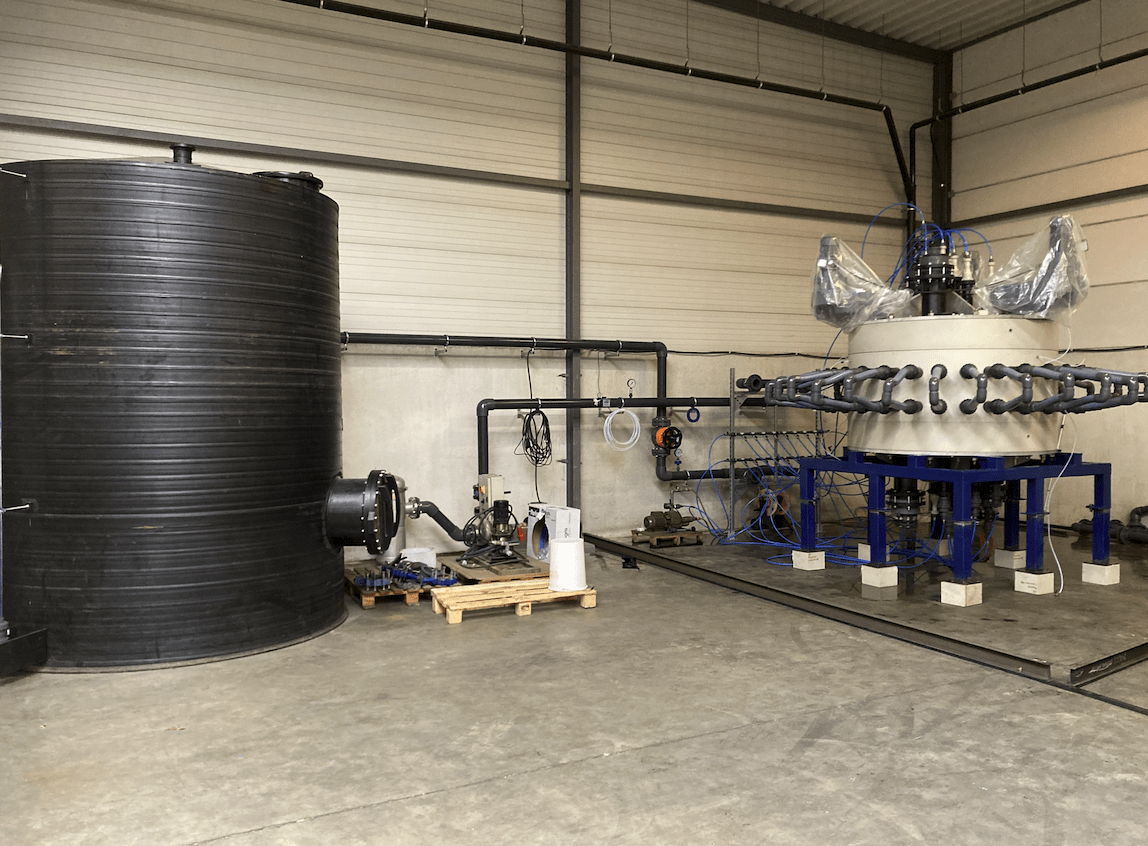

The nickel purification process is very complex of which a few are based on ion exchange, each taking care of a part of the full process cycle. Due to ion exchange specific properties, the best (only) way to do this in an economical way is by continuous counter-current ion exchange like offered by PuriTech's ION-IX technology.

Due to the length of the MTZ (Mass Transfer Zone), the adsorption zone is made out of three stages in series. In this part of the process, nickel will load onto the resin. The exhausted beds move out of the adsorption zone while new regenerated beds come into the adsorption zone at the other end. By using a concentrated acid solution (eluant) the resin will free the adsorbed nickel, while exchanging protons from the acid.

This step will produce a concentrated nickel eluate

Nickel is a hard, silver white metal that has industrial applications related to its strength, corrosion resistance, high ductility, good thermal and electrical conductivity and catalytic properties. Its primary use is in manufacture of stainless steel, steel alloys and superalloys.

The nickel purification process is very complex of which a few are based on ion exchange, each taking care of a part of the full process cycle. Due to ion exchange specific properties, the best (only) way to do this in an economical way is by continuous counter-current ion exchange like offered by PuriTech's ION-IX technology.

Due to the length of the MTZ (Mass Transfer Zone), the adsorption zone is made out of three stages in series. In this part of the process, nickel will load onto the resin. The exhausted beds move out of the adsorption zone while new regenerated beds come into the adsorption zone at the other end. By using a concentrated acid solution (eluant) the resin will free the adsorbed nickel, while exchanging protons from the acid.

This step will produce a concentrated nickel eluate

Thanks to PuriTech's large experience and its ION-IX technology, the best solution for nickel

purification can be offered.