Molybdenum recovery

Molybdenum is commonly found in mineral ores such as molybdenite (MoS2) and wulfenite (PbMoO4).

The primary sources of this remarkable metal include China, the United States, Chile, and Canada.

The extraction involves a complex process of crushing, grinding, and flotation, followed by roasting and purification techniques to obtain pure molybdenum oxide or ferromolybdenum.

One of the major purification and isolation techniques is through ion exchange.

Molybdenum has emerged as a versatile material with a wide array of applications in the technological industry.

Molybdenum is extensively used as an alloying element in steel production. It enhances the strength, toughness, and heat resistance of steel, making it suitable for critical applications such as construction, pipelines, and automotive components.

Due to its excellent electrical conductivity, molybdenum finds applications in the electronics industry. It is used in the production of thin-film transistors, touch screens, and conductive coatings, enabling the development of high-performance electronic devices.

Molybdenum possesses exceptional thermal resistance, making it ideal for applications in aerospace, defense, and power generation sectors.

It is used in jet engines, rocket nozzles, and high-temperature furnaces, where it maintains its strength and structural integrity even at extreme temperatures.

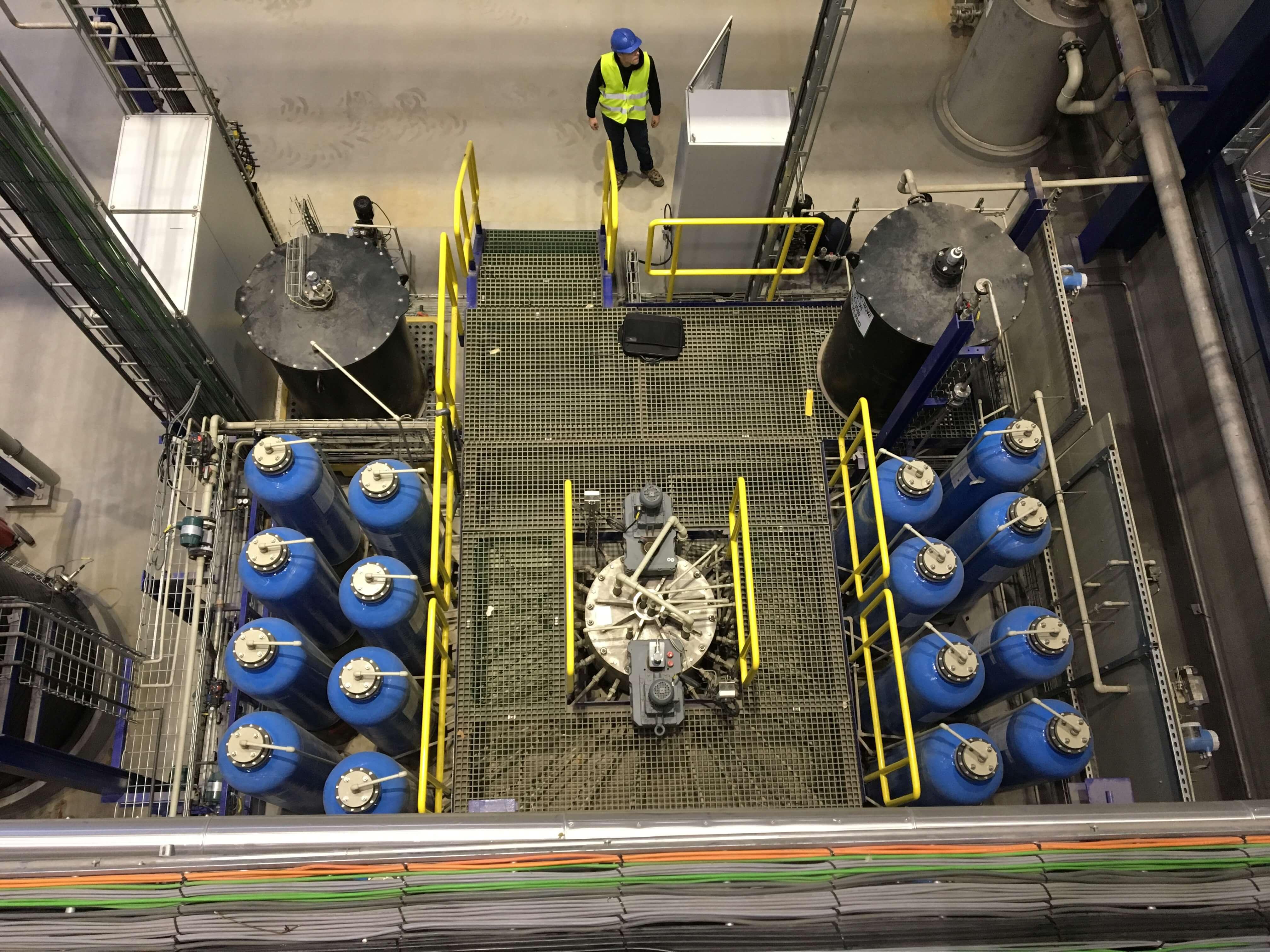

As already described, the go-to process for obtaining Molybdenum is through ion exchange.

More specifically CCIX (continuous counter-current ion exchange) by which molybdenum can be obtained continuously while chemical usage is reduced and operation cost is smaller than in conventional techniques.